VASANTHA TOOL CRAFTS P.LTD.

Featured Products

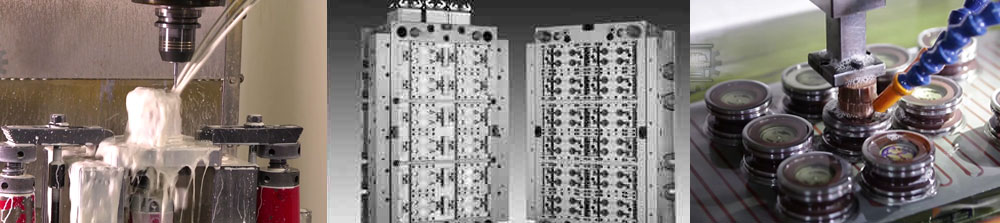

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to VASANTHA TOOL CRAFTS P.LTD.

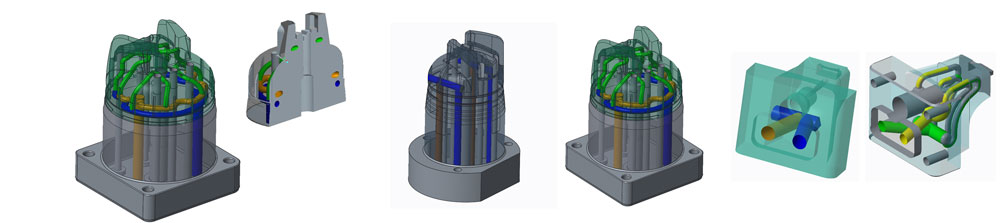

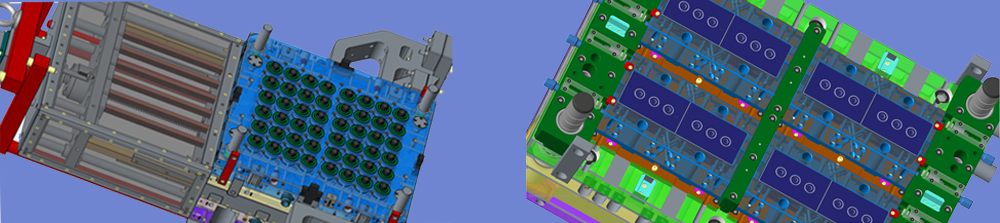

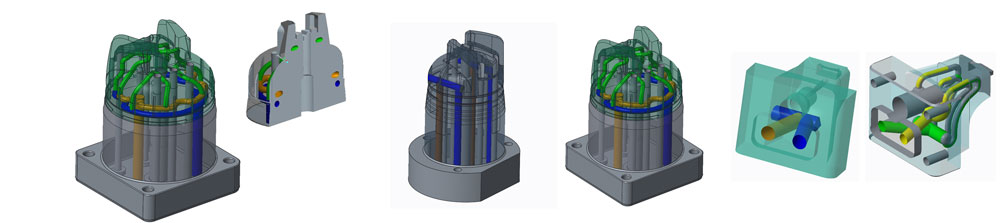

Direct Metal Laser Sintering

Vasantha, keeping in pace with the latest technological advancements in the field of mould making, has inducted leading cutting-edge 3D printing technology into its manufacturing line in the year 2014 for creating the conformal cooling channels in metal inserts.

Vasantha, is probably the only mould design and manufacturing set up in whole of South East Asia to have Direct Metal Laser Sintering ( DMLS) equipment in house.

The equipment from EOS has building capacity by volume - 250 mm x 250 mm x 325 mm (9.85" x 9.85" x 12.8")

Advantages

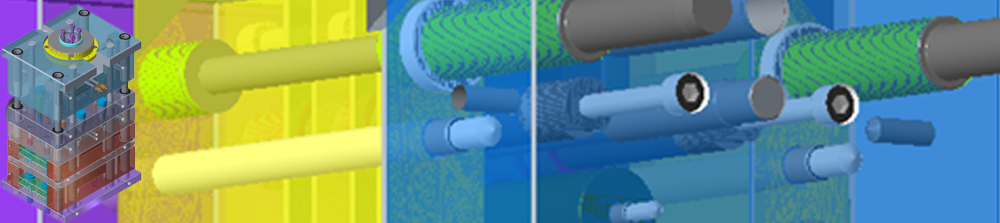

Conventional moulds have straight-line cooling channels.

Conformal cooling follows the geometry of the part to be produced, makes Cooling to reach difficult areas.

Cooling Time reduces by 40% – 60% for complex profiled parts, resulting in shorter cycle times.

A typical cycle-time reduction for a properly engineered mould using conformal cooling can be 30% to 50%.

High Productivity.

Cooling will be uniform, hence controlled warpage & shrink mark.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

54361.jpg)